Since this is a new machine the screw is not worn so backlash should be minimal. I also think on a lathe we rarely need to make cuts that involve direction change- we usually cut on the infeed. If backlash becomes a problem I think my first solution will be to use an epoxy nut, like I did for my Sherline Mill

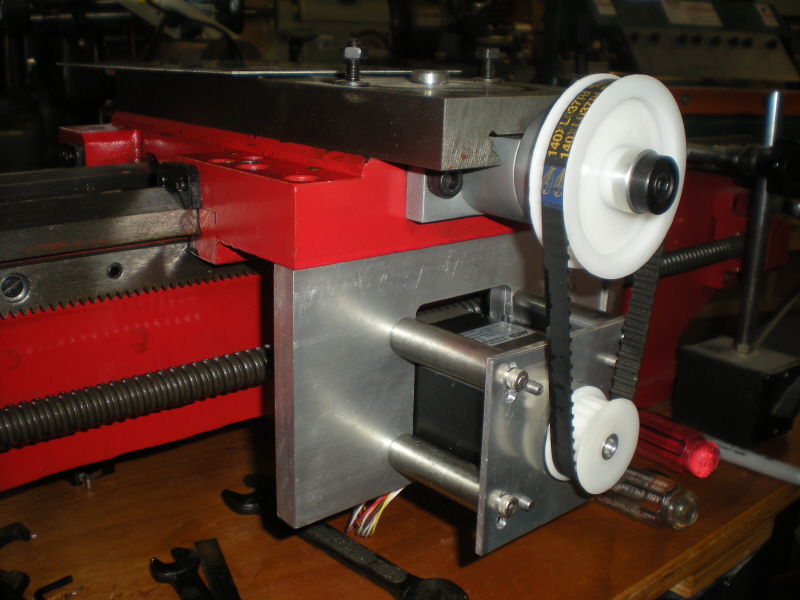

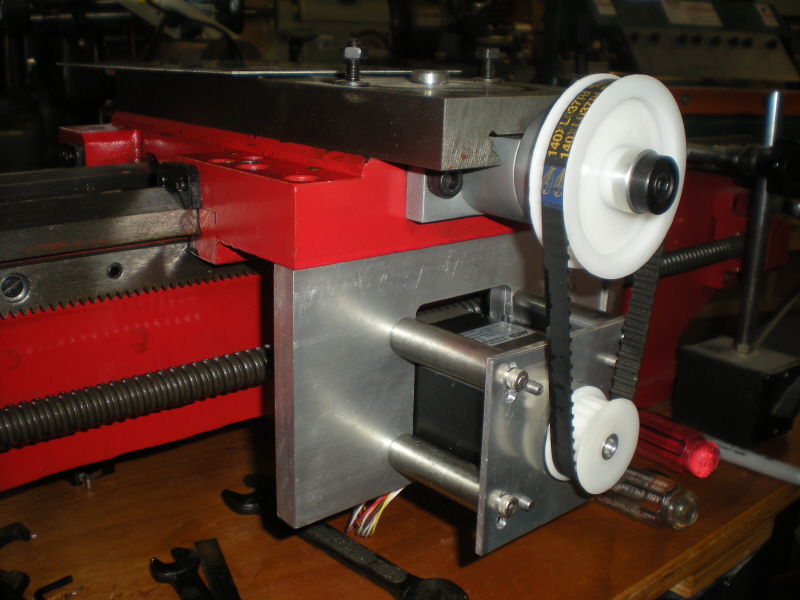

The next issue is how to arrange the drive. I would prefer to have a direct drive, with the stepper right on the end of the screw, but in this case that would have left the motor way out in front of the machine and in the way, so I decided to go with a belt drive. The photo shows the mount for the motor and the belt. The upper pulley was machined exactly like the original handwheel so it fit directly on the screw.

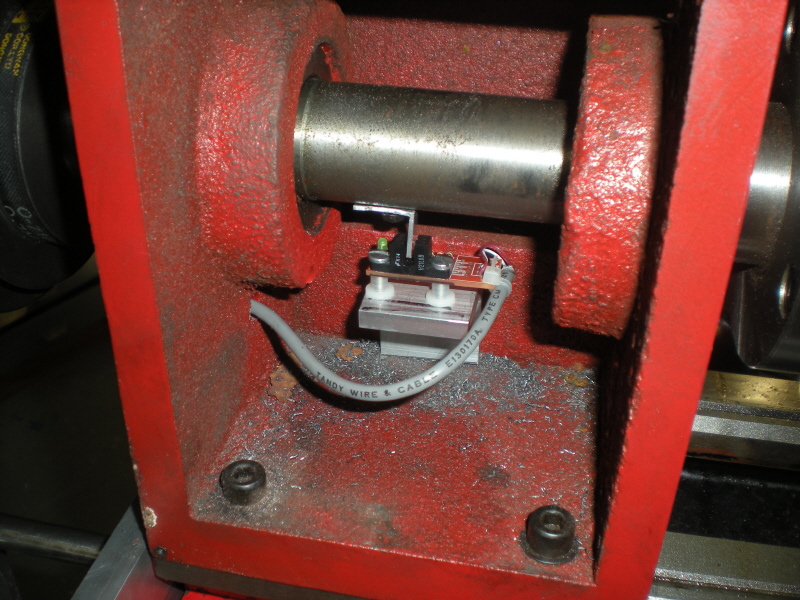

Instead of a wheel with a hole I made a simple piece of aluminum angle to act as a shutter. I tapped a small hole into the spindle and screwed the angle on. Obviously this kind of tab would never work outside the headstock- it would grab every chip and wire on the machine.

For a sensor I used an electronic limit switch from Makerbot. When I ordered them they were under $3 each. Similar sensors are sold by PMDX and CNC4PC

I mounted the sensor on a piece of aluminum angle, and used some plastic standoffs to adjust the height of the board to get the shutter positioned correctly to the sensor.

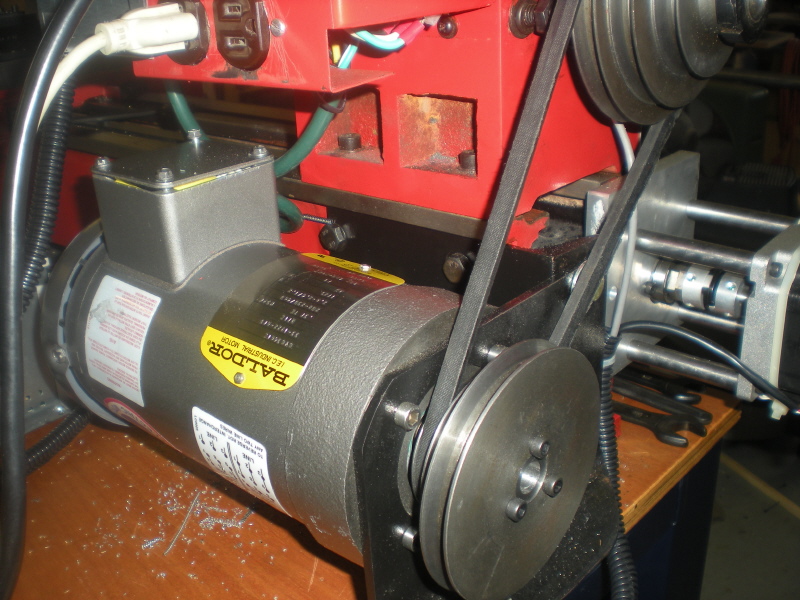

I had to make a new mounting plate for the motor which I made from some 6" channel iron I had in my shop. The motor can swing for changing belts.