At this point I have basically completed the hull and thrusters.

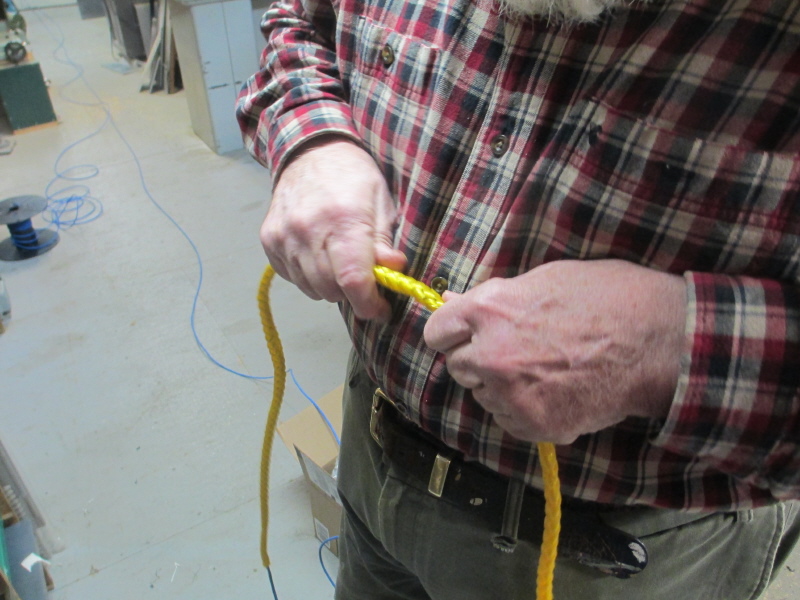

Next I turned to making the tether. For this I bought a chap braided poly rope that is supposed to float. I found some without a center strand, so I pushed the cat5 wire through the center. I hope this combination of floating rope and wire will be about neutrally bouyant. It sounds crazy to push 100 feet of wire through the center of a rope, but it actually worked easier than I thought it would. It did take a couple hours and resulted in a small blister on my hand, but I now have what looks like a great tether.

At the ends I split out the wire so I can have the rope tied to the ROV and to the boat and have the wire run out to the control. I will make a stand to hold this reel and have a crank on it to rewind the tether.

I should have updated this a while ago. My results have not been very good. I have had a LOT of trouble with the arduinos and uploading new code to them to test. I have discovered that code that sends serial data fouls up the bootloader process. I bought a separate loader module from Sparkfun and have some better success, but it is still very slow and painful and with many failures. I do not understand how arduino has become so successful with all the troubles I have had loading. From reading many forums I am not alone.

I did get some code that reads my joysticks, sends it via rs-485 to the ROV and then drives the correct servo motors.

I tried a float test with disastrous results, due to a dumb mistake on my part. When I made the main hull I drilled a circle of holes around the end to hold on the end and press against the O-ring seal. I set the hole depth by measuring the thickness of the PVC sheet I had to make the end. But the clear plexi I used for the camera end was a bit thinner and the screws bottomed before applying pressure to the plexi. Simple solution, I ordered a box of SS washers to add under the screws, but when it came time to do the final assembly I forgot the washers. When we tried the float test the hull rapidly filled with sea water. I was so determined to see the thrusters run that I tried them for a few seconds.

In the end I thoroughly doused the interior and electronics with sea water. That stuff is a terror on electronics. It ruined my Lipo drive battery and the 5v logic battery along with some other wiring.

I put it all aside for a few weeks, then decided to try again. I have water tested the hull with fresh water and no electronics, and renewed all the wiring and electronics. I had all the controls working on the bench, but when I inserted it into the hull I guess some wires came loose because I cannot get it to work now.

I have decided to throw in the towel. I have placed my camera and video monitor on craigslist and would be happy to sell the blue robotics t100 thrusters, with or without the hull. I have many other projects I want to work on and this one has taken all the time I want to put into it.