|

A closer look under the plates at the mounting brackets supporting

the cylinder. |

|

Standing below the chamber looking up at the joint between the chamber

and the fixed lock wall. Surprisingly little leakage |

|

Looking back at the guide rails that keep the chamber aligned so it

doesn't tip over. They look like rather light rails, but everything is

perfectly balanced in that direction, and with water as a load you know its

always distributed uniformly. |

|

This is the main control valve, a butterfly valve operated by

hydraulic cylinders. Originally, until about 1965, it was operated from long

control rods down from the tower above. When it was switched to electro-hydraulic

control the control room was moved back to the main wall.

The yellow pipe coming down carries the makeup water form the electric pumps. |

|

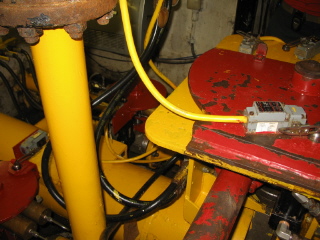

The top of the valve showing the limit switches that signal when the

valve is at the 10% and full open position. When operating they open the valve

slowly, then close it slowly as it reaches the end of the trip to reduce shock

loads. |

|

Here the main pipe exits through the wall to the ram. The smaller pipe is one

of the control lines where water can be added or removed to trim the main system. |

|

This is the electrical to hydraulic panel- electric lines from the

control room operate these solenoids to control the hydraulic flow to

operate both the transfer valve and the gate opening and latching. |

|

Back at ground level, between the locks, looking up toward the central

tower that was the original main control tower. |

|

View of the main lock wall, with the water gate above, and the chamber down. |

Again my thanks to Ed Donald for a great tour.