An Interactive CNC system

I have been tinkering with CNC software for a couple years. Ive played with INDEXER-LPT, BobCAD, MAXNC, and a few 'freeware' packages off the net. None of these struck me as easy to use.

A frined of mine, Roland Gaucher, bought a commercial miling machine and CNC system from AcuRite, with software called MillPower. I learned to use his software in just a few hours, and really liked it, so I decided to try to write something like it. This is not an exact copy, but I did folow their basic concept of use.

First, let me be clear that this software is NOT for sale. So far it has just been an amusement for me, partly to learn to use Visual Basic, partly to make something usefull to me.

I started this work in 1998 or so, and in early 2002 I started to work on a new and improved version. My work has all been around the interface, or GUI part of the problem. I do not want to get into the real time pulse generation problem. I need either a 'black box' of hardware or an interface to some software. I have tried to use MACH2 and DeskCNC but have had trouble with each.

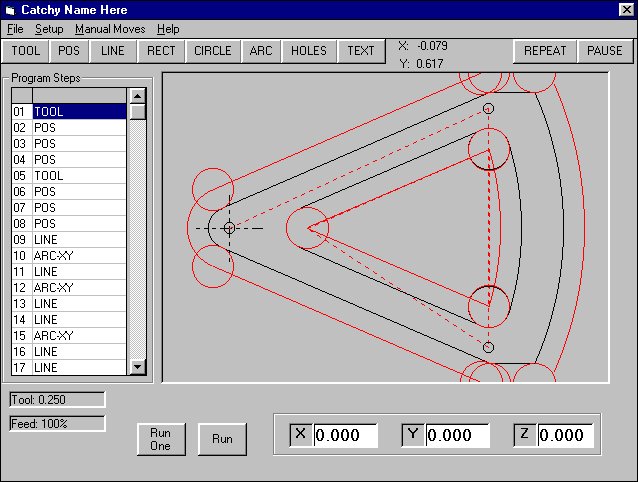

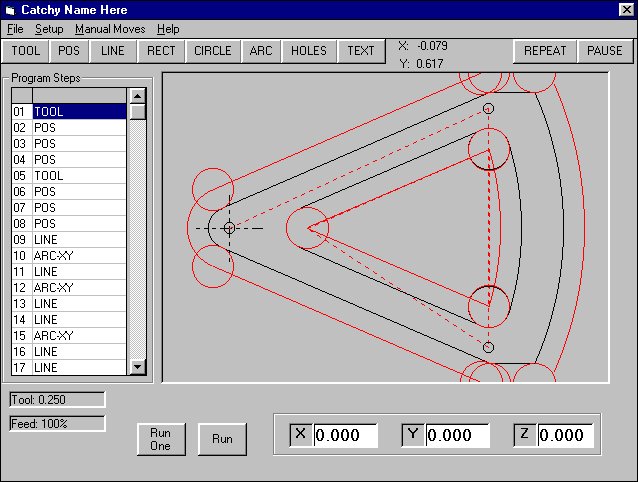

The next image is the main screen, showing a sample part. This part was actualy programmed and then made on the Sherline mill I built, and is part of the reverse gear for Minnie.

The form should be fairly obvious- the area to the left shows the individual steps in this program, the image area shows the part outline in black, and the tool path in red. The red circles indicate where the tool will start and stop various paths. The row of buttons across the top select various objects to add to the program.

Before you can use this system you need to configure the motor control. CNH uses a simple setup screen to select the parallel port pins for each function.

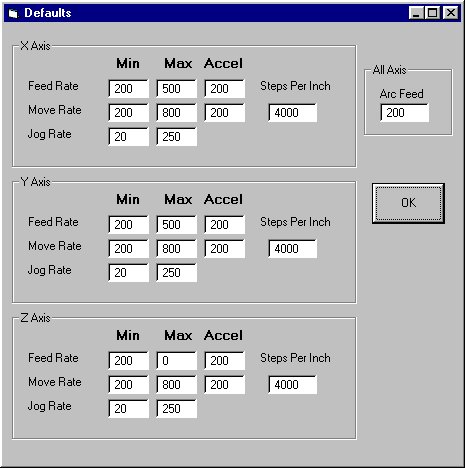

Once the pins are defined, you need to set some parameters for speed and acceleration with this screen

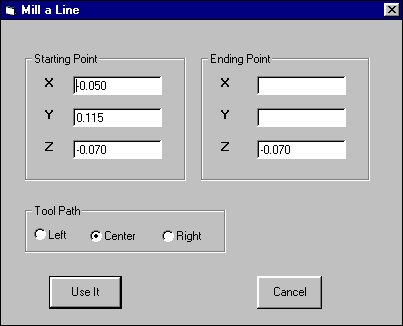

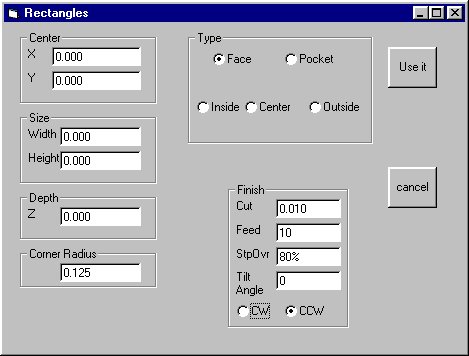

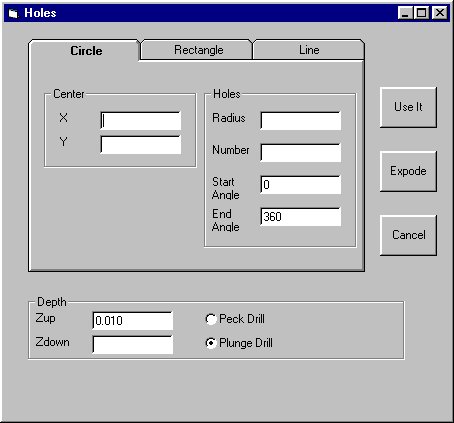

To add features to the program you select a button on the top of the main screen, then an appropriate form opens to build that object. Following is the screen for a line, rectangle and an array of holes. Each of these is a simple 'fill-in the blanks' operation. Note that the program assumes a starting point, based on the last point entered, but that can eaisly be replaced.

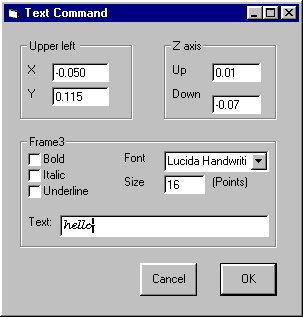

One interesting feature of CNH is the ability to mill True Type fonts. Here is a screen showing text entry.

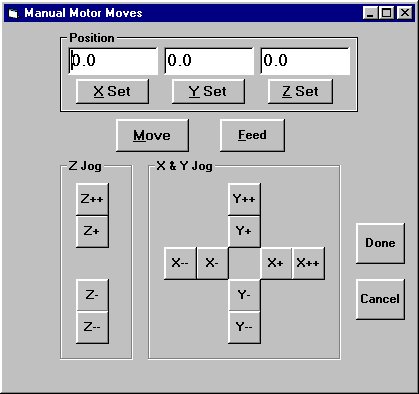

Once a program is built and you are ready to run the part, the following screen opens to allow you to make the initial tool movements, set a reference datum- note it doesnt have to be Zero, you can set the tool datum to any value and the mill will assume that datum is the current tool position.

CNH saves files in an internal form, and can also save files in the same text form as AcuRite uses for their machines. I have created parts file with my program and loaded them onto Rolands machine without problem. I can read into my program G Code files or Excelan drill files for drilling PC boards.