|

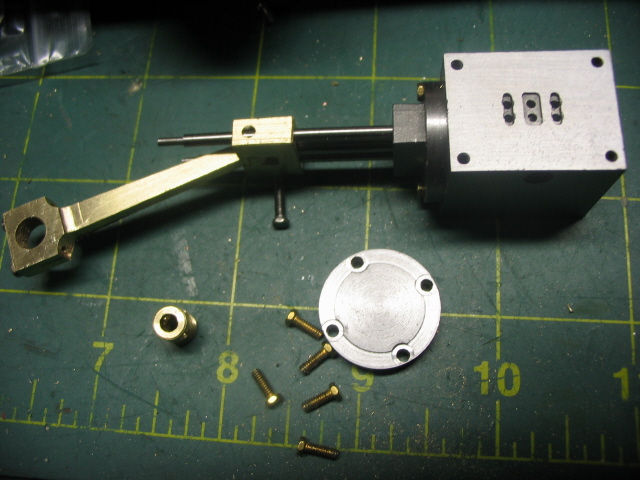

| The cylinder block was cut from a piece of durabar cast iron. I find this

material very nice to work, it cuts and mills just great. The steam passages

are dilled 1/16" dia, and the pors were milled with a 1/16" end mill.

The head is a simple turning job, while the backhead was first milled from square

block, then turned on a spigot threaded into the stuffing box hole. |

|

| Here the connecting rod is being profile milled on the Prazi CNC. Note the

aluminum sacrafice plate under it shows the outline of the side frames, and even

some of the spoke patterns- the same block has been used for all these operations.

When it gets to uneven Ill flycut it flat and use it more. |

|

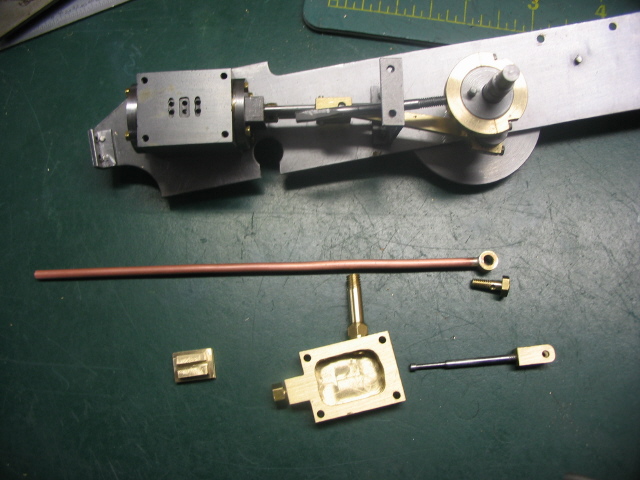

| Here is the block, crosshead, guide bars and connecting rod all assembled. |

|

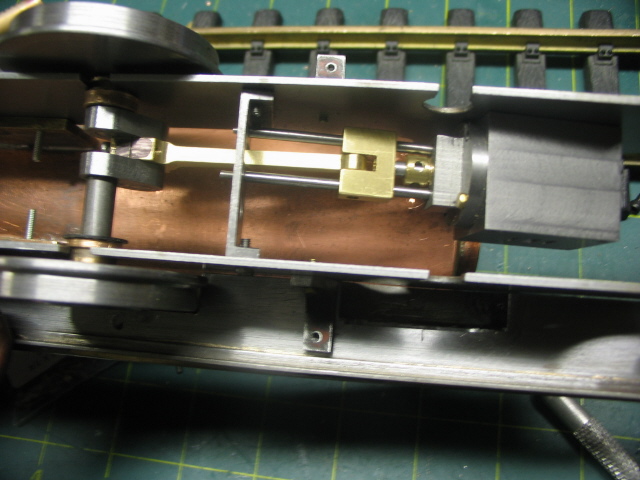

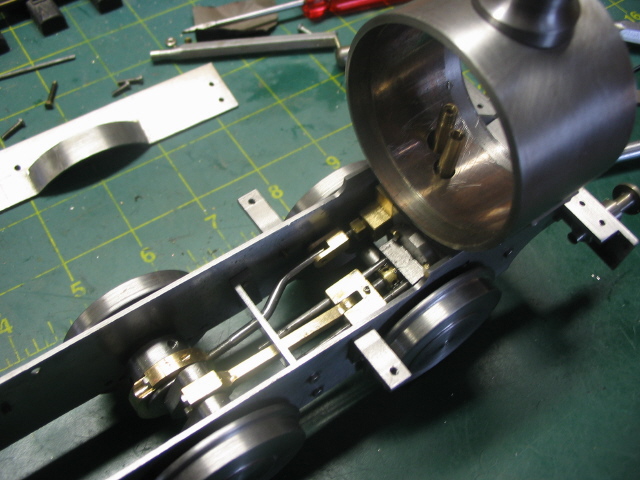

| And here the complete assemply is installed between the frames and hooked

to the crankshaft.

This photo shows another mod I made- the axles are fitted into slots, and held in place with

an E-clip. The original design called for fixed bushes, with the wheels pressed together

and impossible to remove. I can pull the E-clips, slide the buses to the center of the

axle and lift the axle out through the slots. |

|

| Here are the valve parts- the chest, spindle and the actual valve. Also shown os

a banjo fitting and copper pipe that will supply the lubricator oil to the

engine, directly into the valve chest. |

|

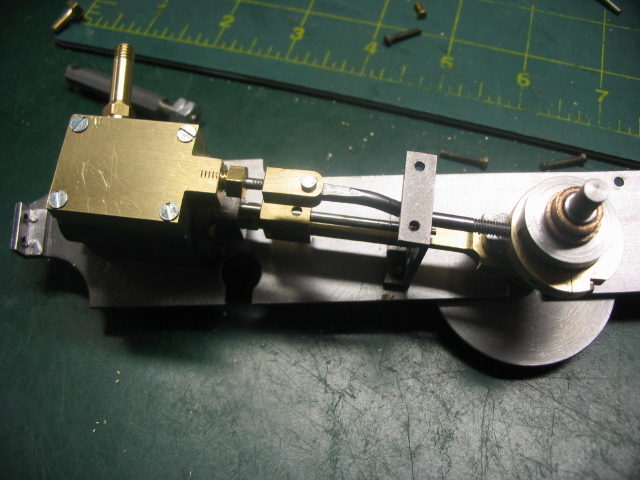

| Here the engine is completely assembled, but the left side frame is not yet

installed. |

|

| The complete engine, between the frames, with the smokebox installed and the

steam pipe up from the eninge into the steambox.

I had a couple days of frustration to get the engine running. I fiddled with

the valve stem adjustment, the eccentric position and even shortened up

the vale as I thought the design had to much lap.

The problem turned out to be the

steam ports were closed off by the small alignment spigot turned on the back of the cylinder covers.

This spigot was deep enough that the small mill cut to deliver steam from the drilled holes

was completely covered on one end, and almost covered on the back end.

I milled a small pocket in the heads and reassembled it all and it ran just fine. |